HH25A hybrid

Features of HH25A hybrid

HH25A(25ton Die Locking force) was developed for energy saving and environment improve,it uses servo

motor at injection side and the other mechanism such as die clamping, ejector, and nozzle touch are using

hydraulic. Use servo motor for injection it make machine injection performance be stable for every shot,

it was easy for setting and control.New design toggle unit,it make locking force concentrate at the centre

of platen. It was improved efficacy and working environment by new develop of hydraulic system with idling

stop function and furnace heating system without gooseneck heater.

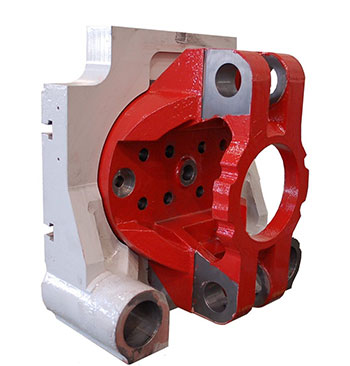

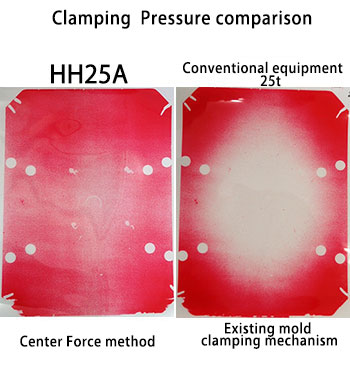

| ▶ New locking system |

|---|

| Die locking mechanism adopts the CENTER FORCE system which pushes

the center of the mold. Bending of a mold is reduced. Furthermore, by abolishing the conventional tie bar guide system and using a linear guide, it has structure which can maintain accuracy more. |

|

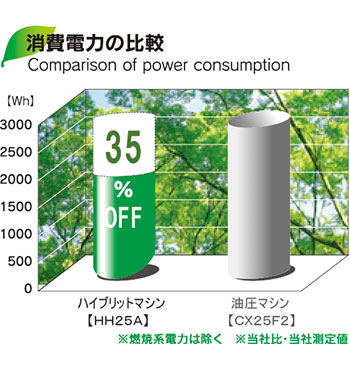

| ▶ Saving energy |

|---|

| About 35% of energy saving is realized by carrying inverter control and an

idling stop function in a hydraulic pump. The capacity of electric furnace

heater is down from 18.6kw to 10kw. About 50% cut of electric power capacity was enabled by gooseneck heaterless system. |

|

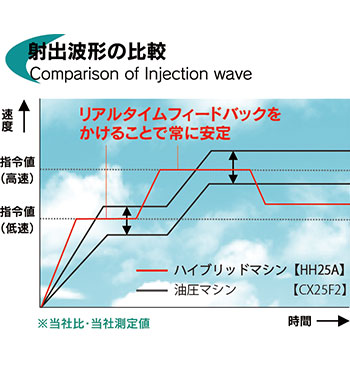

| ▶ Quality improvement |

|---|

| Performing speed feedback with electric servo control, while being affected

to the injection speed by disturbance in the conventional hydraulic type DC

machine, it rectifies and contributes to mass-production with stable quality Moreover, it can be detailed injection setting, such as injection control which makes less the flash by a high response. |

|

State the door is open

Technical Data

| Die locking force | kN | 250 |

| Space between tie bars | mm | 271×271 |

| Die stroke | mm | 160 |

| Die height | mm | 140~330 |

| Maximum Injection force | KN | 32 |

| Injection stroke | mm | 100 |

| Injection position | mm | 0/-40 |

| Ejector force | KN | 21 |

| Ejector stroke | mm | 50 |

| Nozzle touch force | KN | 16 |

| Nozzle touch stroke | mm | 180 |

| Injection plunger diameter | mm | 45 |

| Casting pressure | MPa | 20.1 |

| Casting area (efficiency 100%) | cm2 | 124 |

| Maximum shot weight (efficiency 75%) | kg | 0.81 |

| Dry cycle time | sec | 2 |

| Working pressure | MPa | 10.5 |

| Oil tank capacity | L | 120 |

| Melting pot capacity | kg | 200 |

| Electric motor capacity | kw | 3.7 |

| Power supply capacity | KVA | 43 |

| Output of electric furnace | kw | 10 |

| Machine weight | ton | 3 |

The above specifications may vary depending on the model.

Please note that the above specifications are subject to change without notice.