HC350F

Features of HC200F

200 ton is a new model of HC series

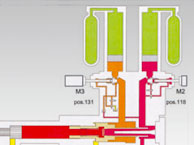

Gull-wing type safety door are use at toggle unit. It makes maintenance be easy.

Built in Check valve injection cylinder, it reduce time lag from high speed phase change to intensification phase.

HC Series Features

Small cold chamber die casting machine serialization.

Product quality improves by shifting to minority Cavity mold design from multi-cavity.

Standard equipped multi ‒ language touch-panel.

STANDARD

| ▶ Injection twin circuit | ▶ Injection digital control |

|---|---|

The twin intensification circuit, it makes freely to set the position, it satisfy all kinds of processing requirements. (Exclude HC50F and HC200F) |

Injection lower speed logic valve can be set from 0.1~0.5 m/s easily.Injection high speed valve control by motor, it can easy to setting by touch panel. |

| ▶ Injection position switching function | ▶ Multilingual touch panel display |

|---|---|

Injection position is not fixed, it's easy to located the die to fit the die platen.(Exclude HC50F) |

Standard equipped multi ‒ language TFT touch-panel display. (Japanese, English, Chinese, Korean, Thai) |

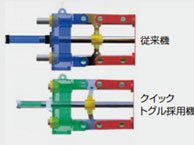

| ▶ Quick toggle | |

|---|---|

Quick toggle for die locking unit.(Exclude HC50F) |

OPTION

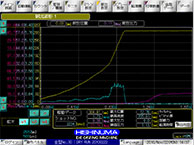

| ▶ Injection waveform monitoring device | ▶ Clamping force display |

|---|---|

Displays injection wave(position, speed and pressure), and grasp of relevant casting conditions. |

Displays the die locking force digitally. When die locking force was except a rated value, the safety circuit works to stop the injection. |

| ▶ Motor-driven safety door | |

|---|---|

The motor-drive safety door reduces the failure rate of long duration operations and shorten the door opening / closing time. |

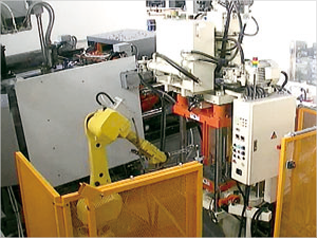

PERIPHERAL EQUIPMENT

| ▶ Spray dispensing apparatus | ▶ Fully automatic water heater |

|---|---|

Extractor and spray unit work at the same line, it makes space saving |

The ladle works smoothly by inverter control. |

| ▶ Servo trimming device |

|---|

Possible to set arbitrary for descend speed and torque. It can be set the best operation matched to various purposes. |

Technical Data

| Die locking force | 2000kN |

| Space between tie bars | 530×530mm |

| Die stroke | 450mm(Variable) |

| Die height | 300~600mm |

| Maximum Injection force | 215kN |

| Intensification ratio | 1 : 2 |

| Injection stroke | 370mm |

| Injection position | 0mm, -125mm |

| Tip projection | 150mm |

| Plunger tip diameter | 50mm |

| Ejector force | 116kN |

| Ejector stroke | 100kn |

| Electric motor |

22kw |

| Electric power | 35KVA |

| Oil tank capacity | 500L |

| Weight of machine | 10ton |

The above specifications may vary depending on the model.

Please note that the above specifications are subject to change without notice.