HC100F

Features of HC100F

High cycle casting was realized by high-speed die locking and quick toggle.

Digital control is possible by injection lower speed logic valve and injection high speed valve control by motor.

3 stages injection position (0,-50,-100)

HC Series Features

Small cold chamber die casting machine serialization.

Product quality improves by shifting to minority Cavity mold design from multi-cavity.

Standard equipped multi ‒ language touch-panel.

STANDARD

| ▶ Injection twin circuit | ▶ Injection digital control |

|---|---|

The twin intensification circuit, it makes freely to set the position, it satisfy all kinds of processing requirements. (Exclude HC50F and HC200F) |

Injection lower speed logic valve can be set from 0.1~0.5 m/s easily.Injection high speed valve control by motor, it can easy to setting by touch panel. |

| ▶ Injection position switching function | ▶ Multilingual touch panel display |

|---|---|

Injection position is not fixed, it's easy to located the die to fit the die platen.(Exclude HC50F) |

Standard equipped multi ‒ language TFT touch-panel display. (Japanese, English, Chinese, Korean, Thai) |

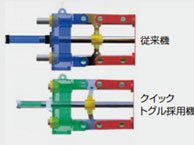

| ▶ Quick toggle | |

|---|---|

Quick toggle for die locking unit.(Exclude HC50F) |

OPTION

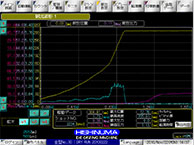

| ▶ Injection waveform monitoring device | ▶ Clamping force display |

|---|---|

Displays injection wave(position, speed and pressure), and grasp of relevant casting conditions. |

Displays the die locking force digitally. When die locking force was except a rated value, the safety circuit works to stop the injection. |

| ▶ Motor-driven safety door | |

|---|---|

The motor-drive safety door reduces the failure rate of long duration operations and shorten the door opening / closing time. |

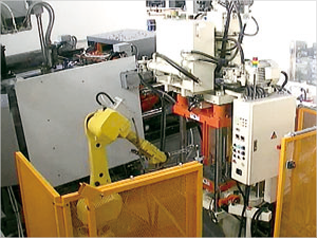

PERIPHERAL EQUIPMENT

| ▶ Spray dispensing apparatus | ▶ Fully automatic water heater |

|---|---|

Extractor and spray unit work at the same line, it makes space saving |

The ladle works smoothly by inverter control. |

| ▶ Servo trimming device |

|---|

Possible to set arbitrary for descend speed and torque. It can be set the best operation matched to various purposes. |

Technical Data

| Die locking force | 1000kN |

| Space between tie bars | 425×425mm |

| Die stroke | 340mm(Variable) |

| Die height | 250~500mm |

| Maximum Injection force | 159kN |

| Intensification ratio | 1 : 2 |

| Injection stroke | 305mm |

| Injection position | 0mm, -50mm, -100mm |

| Tip projection | 125mm |

| Plunger tip diameter | 50mm |

| Ejector force | 70kN |

| Ejector stroke | 75kn |

| Electric motor |

15kw |

| Electric power | 17KVA |

| Oil tank capacity | 300L |

| Weight of machine | 6ton |

The above specifications may vary depending on the model.

Please note that the above specifications are subject to change without notice.