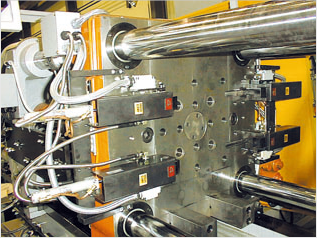

CXMG 250

CXMG Series Features

Advanced magnesium hot chamber die casting machines serialization.

Excellent stability and durability which enabled prolonged high cycle casting continuously.

Standard equipped multi-language touch panel and piston type accumulator.

Maximum injection speed realized 6m/sec by dry shot.

STANDARD

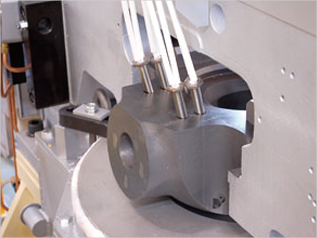

| ▶ High-speed injection equipment | ▶ Nozzle touch cylinder |

|---|---|

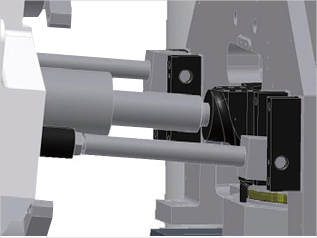

Logic valve and piston type accumulator on the higher speed injector enable constant injection and product quality. Maximum injection speed 6m/sec by dry shot achieved. |

By shifting the nozzle touch cylinder at the operation side and helper side, it improved the maintenance works around injection nozzle. |

| ▶ Withdrawal ShikiToru flash furnace | ▶ Multilingual touch panel display |

|---|---|

Drawer type melting furnace, it makes heating element exchange work be easy. |

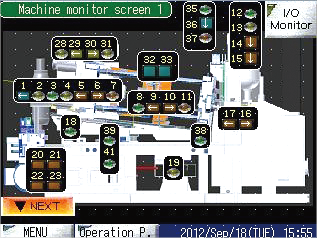

Standard equipped multi ‒ language TFT touch-panel display. (Japanese, English, Chinese, Korean, Thai) |

OPTION

| ▶ Injection waveform monitoring device | ▶ Clamping force display |

|---|---|

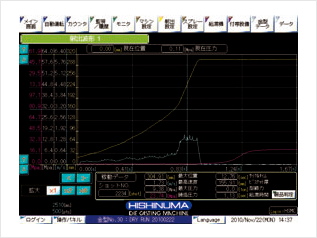

Displays injection wave(position, speed and pressure), and grasp of relevant casting conditions. |

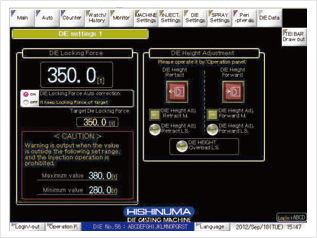

Displays the die locking force digitally. When die locking force was except a rated value, the safety circuit works to stop the injection. |

| ▶ Nozzle heater | ▶ Gooseneck heater |

|---|---|

Improves working environment by heating a nozzle equally, and it makes stable casting. |

Since a gooseneck is heated with a heater, it contributestoimprovementinwork environment and prevents gas entering into a furnace, also leads to reduction of an oxide. |

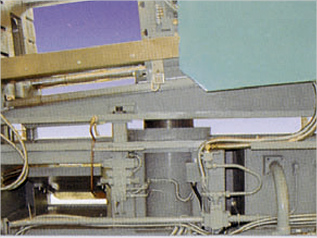

| ▶ Hydraulic jack-up system | ▶ Motor drive safety door |

|---|---|

The central hydraulic jack up system allows easy injection position changing. |

The motor-drive safety door reduces the failure rate of long duration operations and shorten the door opening / closing time. |

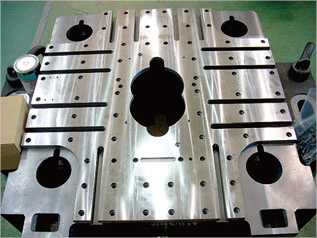

| ▶ Sub-plate |

|---|

By attaching the exchangeable steel plate to platen, it is reduction of the maintenance cost. |

Peripheral equipment

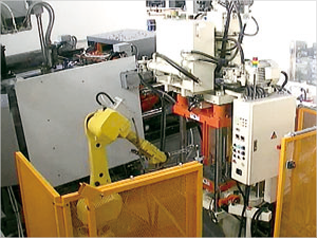

| ▶ Hydraulic automatic clamp | ▶Ingot preheating automatic insertion equipment |

|---|---|

Hydraulic mold clamping, it can easy to mold exchange safely in a short time. |

The preheated ingot is supplied automatically, it can easy to control the metal level. |

| ▶ Mold temperature controller |

|---|

Management of mold temperature is indispensable to mass production of high precision products. |

Technical Data

| Die locking force | kN | 2500 |

| Space between tie bars | mm | 530×530 |

| Die stroke | mm | 450 |

| Die height | mm | 300~600 |

| Injection force | KN | 126 |

| Injection stroke | mm | 200 |

| Injection position | mm | 0/-125 |

| Ejection force | KN | 116 |

| Ejector stroke | mm | 100 |

| Nozzle touch force | KN | 72 |

| Nozzle touch stroke | mm | 400 |

| Injection plunger diameter | mm | Φ70/75 |

| Casting pressure | MPa | 32/28 |

| Casting area (efficiency 100%) | cm2 | 762/893 |

| Maximum shot weight (efficiency 75%) | kg | 1.04/1.20 |

| Dry cycle time | sec | 4.8 |

| Working pressure | MPa | 14 |

| Oil tank capacity | L | 500 |

| Melting pot capacity | kg | 350 |

| Electric motor capacity | kw | 22 |

| Power supply capacity | KVA | 32 |

| Output of electric furnace | kw | 62.3 |

| Machine weight | ton | 12 |

The above specifications may vary depending on the model.

Please note that the above specifications are subject to change without notice.