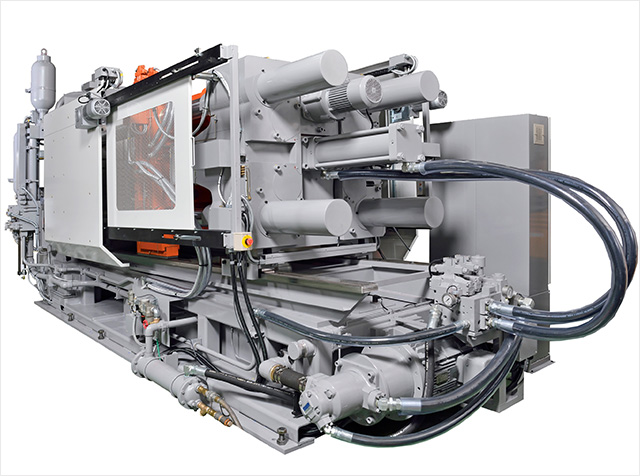

CX150F3

Feature of machine

●Standard equipped with PLC control system and LCD touch panel.

●Corresponds to many languages such as Japan, the English, Chinese, Korean, Thai etc.

●Possible to manage temperature and injection condition through touch panel

●Space between tie bars is 460x460mm.

Possible to remote control the speed and pressure of Die locking,

Ejector and Core puller. (Standard of over150t.)

Possible to set each heater temperature and alarm Equipped with temperature graph function.

New design focused on functionality and safety. Improved workability by ensuring the space.

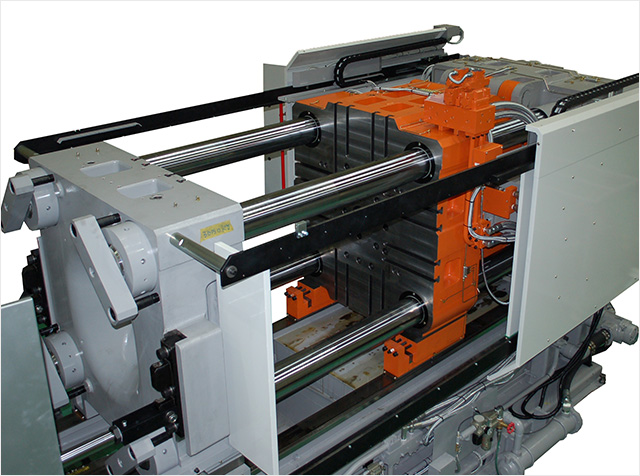

Possible to remote control each speed and pressure of Die locking, Ejector and core puller by proportional valve. (Standard of over 150t)

Enhance performance and stability by logic valve. Easy to setting injection speed exchange by limit switch

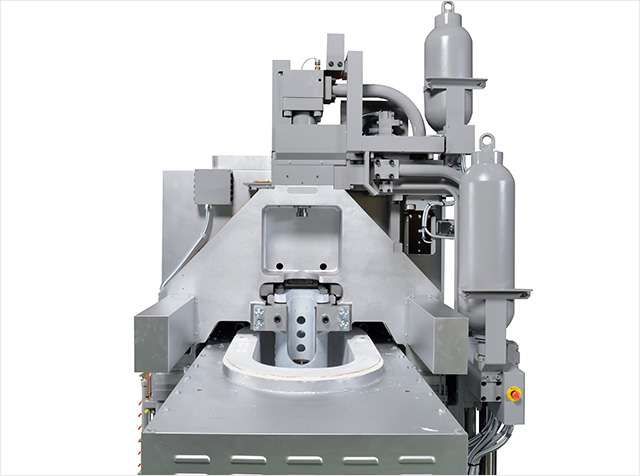

Due to stress analysis and years of accumulated know-how, A high precision, high rigidity, long-life mold clamping device is realized.

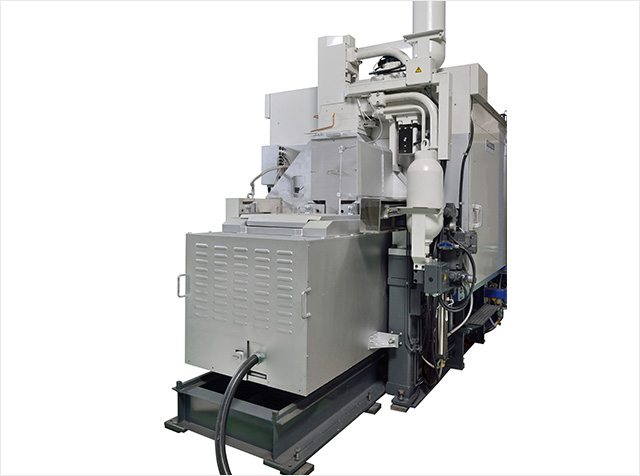

Easy to change the heater by pull-out the furnace Realize the stable temperature control and clean working environment.

Technical Data

| Die locking force | kN | 1500 |

| Space between tie bars | mm | 460×460 |

| Die stroke | mm | 380 |

| Die height | mm | 220~500 |

| Injection force | KN | 99.7 |

| Injection stroke | mm | 200 |

| Injection position | mm | 0/-100 |

| Ejector force | KN | 85.5 |

| Ejector stroke | mm | 90 |

| Nozzle touch force | KN | 72 |

| Nozzle touch stroke | mm | 300 |

| Injection plunger diameter | mm | 65 |

| Casting pressure | MPa | 30 |

| Casting area (efficiency 100%) | cm2 | 498 |

| Maximum shot weight (efficiency 75%) | kg | 3.38 |

| Dry cycle time | sec | 4.5 |

| Working pressure | MPa | 10.5 |

| Oil tank capacity | L | 350 |

| Melting pot capacity | kg | 500 |

| Electric motor capacity | kw | 18.5 |

| Power supply capacity | KVA | 30 |

| Output of electric furnace | kw | 58 |

| Machine weight | ton | 8 |

The above specifications may vary depending on the model.

Please understand that the above specifications may be changed without notice.