U4

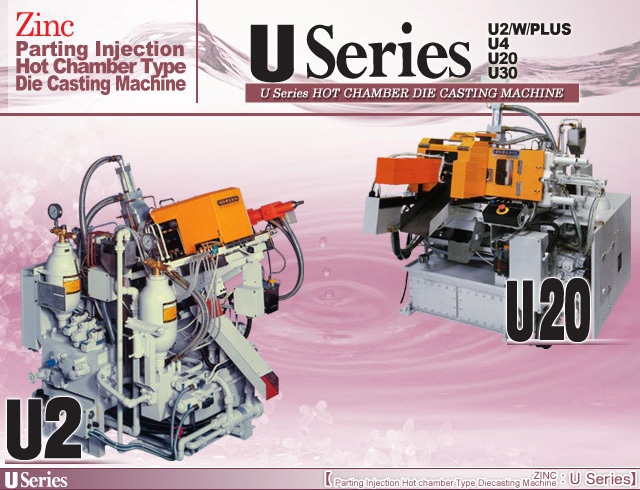

U2 SPRUELESS PARTING INJECTION HOT CHAMBER TYPE DIE CASTING MACHINE

High cycle and super precision Die Casting Machine U2 has renewed the image of old small type Zn Die Casting Machine. It has unique die locking layout and injection system resulting in realized high Productivity. This small type hydraulic die casting machine is most suitable to casting for the super precision parts and electric parts.The die open/die close times have been reduced due to the shorter stroke required with the Sprueless sysem. Directinjection of metal at the parting line reduced areas for air entrapment resulting in small injection amount per shot. By small size designed machine, possible to install the machine in half space currently in use.

Die installation has become easier due to small die and it needs only small amount of Water of spray and cooling.

【U2 System Composition】

■ INJECTION

By equipped Injection logic valve and exclusive accumulator on the same manifold, it makes improve and stability for Injection performance. It made possible easily adjustment injection speed/injection pressure.

Standard equipped pressure gauge and safety valve.

■ DIE LOCKING

Compact type die locking system is manufactured precisely and quenching with tie bar and bushing. Possible to operate by minimum stroke for the production by die locking stroke control system.

Standard equipped electric centralized lubrication device.

■ NOZZLE TOUCH

By Nozzle Touch Hydraulic Clamp system, movement of DIE LOCKING UNIT has become easier and it makes machine more productivity and easy maintenance

■ MELTING SYSTEM

By Electric heater system with Melting furnace and nozzle heating, it makes clean working environment.

■ ELECTRIC CONTRO

Standard equipped Sequencer Control system and Liquid Crystal color display touch panel.

U2【U-Twenty】

The latest Model U20 Die Casting Machine has the capacity to hold dies up to 200×215mm In size, allowing for the production of High Precision "Optical Base " components and mobile Phone parts, which were not possible on the smaller U2 Die Casting Machine. By incorporating the Double Toggle System, die changes and ejector rod connecting has become easier.

Comparison of current type Die Casting Machine and Parting Injection type Die Casting Machine

【U20 system Composition】

■ Direct injection of metal at the parting line reduces areas for air entrapment resulting in better metal flow to the cavities. ■ The die open/die close times have been reduced due to the shorter stroke required with the Sprueless System.

■ With the Parting Line Injection system, less metal is required due to the lack of a sprue, which in turn lowers re-melt costs.

■ With the shorter cycle times required by the U20 machine, this machine is capable of running twice as fast as a conventional 25ton machine.

The above mentioned specifications may differ depending on the model.

The above mentioned specifications may change without a preliminary announcement.