U2ZR

1 second cycle! Ultra-high-speed hot chamber

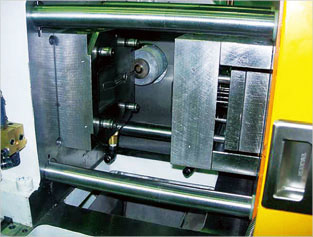

U2ZR is a newly developed super high-cycle parting injection hot chamber die casting machine. It is evolution from our exiting parting injection machine and aim at 1 second cycle time mark production by newest die locking mechanism. The improvement of steady productivity is achieved.Using 2 tie bar close toggle mechanism unit, it make die change work become convenience

and faster.

U Series Features

Less air trapped in the metal flow during die fill, it makes the casting parts excellent.

With parting injection system, it makes less re-melting material and can reduce a lot of re-melting cost.

Sprueless system it makes die opening stroke shorter.

STANDARD

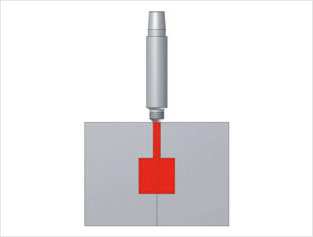

| ▶ Parting injection |

|---|

The sprueless casting has been resulted by direct injection of metal at the parting line.The parting line injection system has resulted in constant higher cycle casting by reducing areas for air entrapment in the casting. |

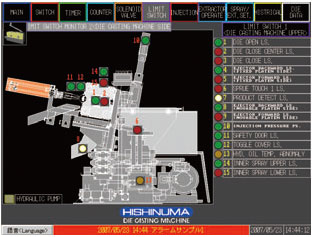

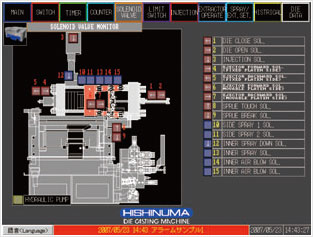

| ▶ Touch panel monitor |

|---|

The standard equipped touch panel display makes easy management of machinepossible.It assists by displaying optimum settings for the various kinds of die, monitoring the machine performance, management of injection parts and stores the alarm records.Multi Languages: multiple languages may be displayedthis is an option.(Languages displayable: Japanese, English, Chinese, Korean and Thai ) |

Comparison of Horizontal die-casting machine and Parting injection die casting machine

| ▶ Horizontal die-casting machine(25ton) | ▶ Parting injection die casting machine(U20) |

|---|---|

|

|

| 1cavity/shot | Casting weight | Scrap weight | |

| 25ton | 13sec/shot | 24.202g | 60.87g |

| U20 | 5sec/shot | 24.263g | 20.8g |

| 8ton | 6sec/shot | 2.5g | 7.4g |

| U2W | 2.5sec/shot | 2.5g | 3.3g |

| ▶ Horizontal die-casting machine(8ton) | ▶ Parting injection die casting machine(U2W) |

|---|---|

|

|

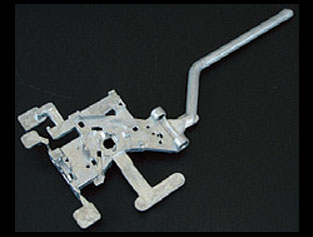

【Casting sample】

OPTIONAL EQUIPMENT

| ▶ Product take-out apparatus |

Accurate detecting and handling of the casting reduces possible damage to both the die and casting. |

| ▶ Injection waveform monitor |

Assists the operator in obtaining the optimum setting of injection plunger position, injection speed and pressure. Adopted a long-life non-contact position sensor. |

| ▶ Medium blow spray device |

High speed inner spray device corresponding to the parting injection system. The die lubricant is reliably sprayed onto the complex-shaped die without slowing the cycle time. |

Technical Data

| Die locking force | kN | 50 |

| Space between tie bars | mm | 140*95 |

| Die stroke | mm | 20~76 |

| Die height | mm | - |

| Injection force | KN | 11.9 |

| Injection stroke | mm | 60 |

| Ejector force/Fixed die ejection force | KN | 10.7 |

| Ejector stroke/Fixed die ejection stroke | mm | 25 |

| Core puler cylinder force/Movable die ejection force |

KN | 10 |

| Core puler cylinder stroke/Movable die ejection stroke | mm | 25 |

| Nozzle touch force | KN | 8.79 |

| Nozzle touch stroke | mm | 120 |

| Injection plunger diameter | mm | 25 |

| Casting pressure | MPa | 24.3 |

| Casting area (efficiency 100%) | cm2 | 21 |

| Maximum shot weight (efficiency 75%) | g | 150 |

| Dry cycle time | sec | 1 |

| Working pressure | MPa | 8 |

| Oil tank capacity | L | 150 |

| Electric motor capacity | kw | 5.5 |

| Melting pot capacity | kg | 90 |

| Power supply capacity | KVA | 6 |

| Output of electric furnace | kw | 10 |

| Machine weight | ton | 1.7 |

The above specifications may vary depending on the model.

Please note that the above specifications are subject to change without notice.